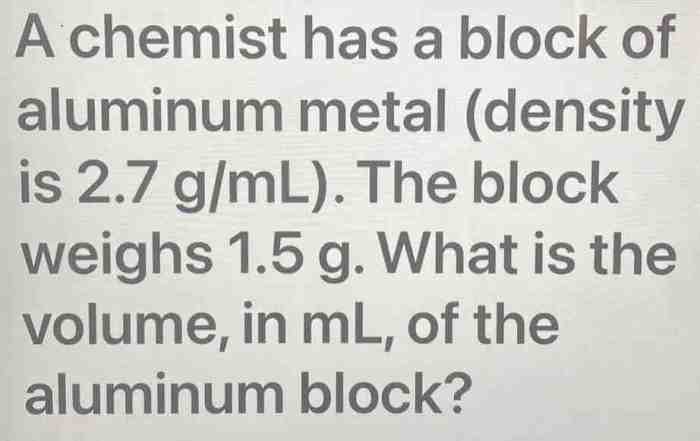

A chemist has a block of aluminum metal, a material with remarkable properties and a wide range of applications. Aluminum’s unique combination of lightness, strength, and corrosion resistance makes it a valuable asset in industries such as transportation, construction, and electronics.

This comprehensive exploration delves into the chemical and physical properties of aluminum, its production process, and the safety considerations associated with its use. By examining the various alloys of aluminum and their specific applications, we gain a deeper understanding of this versatile metal and its impact on modern society.

Chemical Properties of Aluminum

Aluminum is a highly reactive metal with a strong affinity for oxygen. It readily forms a thin, protective layer of aluminum oxide on its surface, which prevents further oxidation and corrosion. This property makes aluminum resistant to most acids and bases.

Aluminum is also a good thermal conductor, meaning it can transfer heat quickly and efficiently. This property makes it useful in applications where heat dissipation is important, such as in heat sinks and cookware.

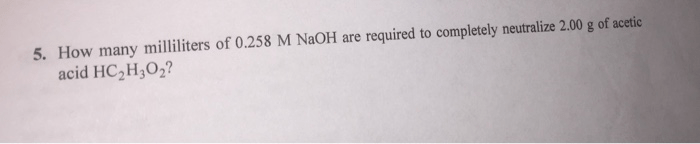

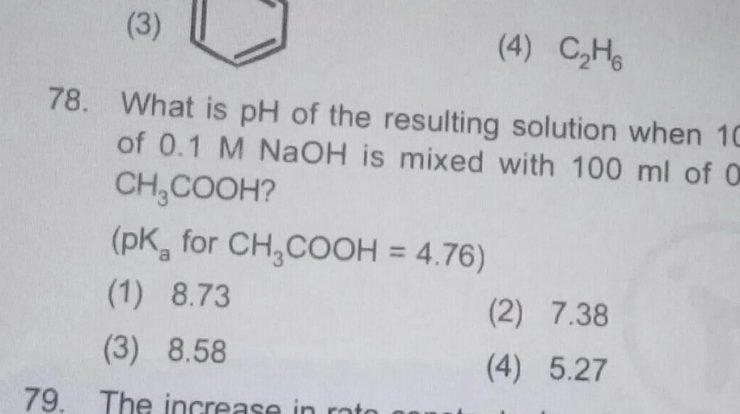

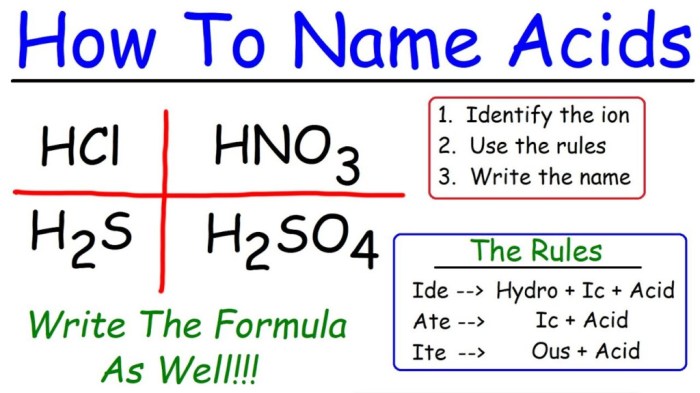

Aluminum reacts with strong acids, such as hydrochloric acid (HCl) and sulfuric acid (H2SO4), to form aluminum salts and hydrogen gas. It also reacts with strong bases, such as sodium hydroxide (NaOH) and potassium hydroxide (KOH), to form aluminates and hydrogen gas.

Physical Properties of Aluminum

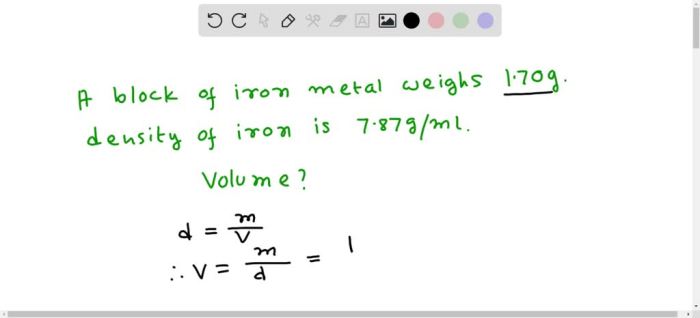

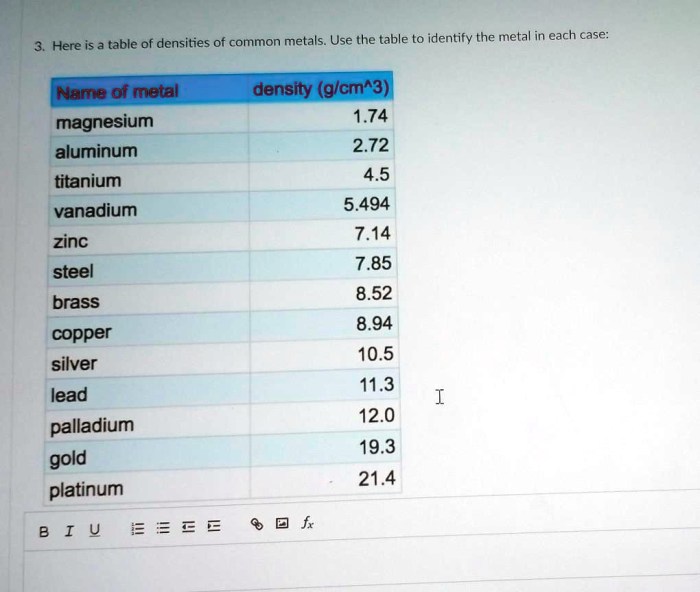

Aluminum is a lightweight metal with a density of 2.70 g/cm 3. It has a low melting point of 660.32 °C and a high boiling point of 2519 °C.

Aluminum is a good electrical conductor, with a conductivity of 37.7 MS/m. It is also a ductile and malleable metal, meaning it can be easily shaped and formed.

The low density and high strength-to-weight ratio of aluminum make it a valuable material for applications where weight reduction is important, such as in aerospace and automotive industries.

Applications of Aluminum

Aluminum is a versatile metal with a wide range of applications in various industries.

- Transportation:Aluminum is used in the construction of aircraft, automobiles, and other vehicles due to its lightweight and high strength.

- Construction:Aluminum is used in roofing, siding, and other building materials due to its corrosion resistance and durability.

- Electronics:Aluminum is used in electrical wires, capacitors, and other electronic components due to its high electrical conductivity.

- Packaging:Aluminum is used in the production of cans, foils, and other packaging materials due to its barrier properties and ability to preserve food.

Production of Aluminum

Aluminum is produced from bauxite ore, which is the primary source of aluminum. The process of aluminum production involves two main steps:

- Extraction of aluminum from bauxite ore:Bauxite ore is crushed and treated with a strong base, such as sodium hydroxide, to dissolve the aluminum compounds. The aluminum compounds are then precipitated from the solution as aluminum hydroxide.

- Electrolysis of aluminum oxide:Aluminum hydroxide is converted to aluminum oxide (Al2O3) by heating it at high temperatures. The aluminum oxide is then dissolved in a molten electrolyte and electrolyzed to produce pure aluminum.

The production of aluminum is an energy-intensive process, and it also generates significant amounts of waste, including spent pot lining and red mud.

Alloys of Aluminum

Aluminum alloys are created by combining aluminum with other elements, such as copper, manganese, silicon, and magnesium. These alloys have improved properties compared to pure aluminum, such as increased strength, hardness, and corrosion resistance.

- 6061 aluminum alloy:This alloy is commonly used in structural applications, such as in building frames and bridges, due to its good strength and weldability.

- 7075 aluminum alloy:This alloy is used in aerospace applications, such as in aircraft wings and fuselages, due to its high strength and fatigue resistance.

Safety Considerations

Aluminum is a combustible material and can release toxic fumes when heated or burned. It is also reactive with certain chemicals, such as strong acids and bases.

When working with aluminum, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, eye protection, and a respirator.

- Work in a well-ventilated area.

- Avoid contact with open flames or sparks.

- Store aluminum in a dry and cool place.

Frequently Asked Questions: A Chemist Has A Block Of Aluminum Metal

What are the key chemical properties of aluminum?

Aluminum is highly reactive, readily forming compounds with other elements. It exhibits strong oxidation resistance due to the formation of a protective oxide layer on its surface.

What are the significant physical properties of aluminum?

Aluminum has a low density, making it lightweight, yet it possesses high strength, resulting in an excellent strength-to-weight ratio. It is also an excellent conductor of electricity and heat.

How is aluminum produced?

Aluminum is produced through a two-step process involving the extraction of aluminum oxide from bauxite ore and the subsequent electrolysis of the oxide to yield pure aluminum.